PROFILE

It was 2000 when Mayur Industries was established to manufacture precision screws and cold formed fasteners with ISO 9001 : 2008 certification on tiny basis. Gradually and steadily the progress was on the way towards the success and achieved the Land Mark of more than 40,000 kgs of manufacturing and supply various industry in all over India as well as abroad in the year 2015.

Mr. Abhijeet and Mr. Rutvik Patel being a dynamic personality, the company under his experience, expert guidance and with a well qualified team of engineers started developing varieties types and size of making a “WIDE RANGE WIDE CHOICE” for the customer. Customers are always looking for one stop solution provider for all range, so we are dedicated to supply range of Machine Screw, Self Tapping Screw, Chipboard Screw, Drywall Screw, Set Screw, Sems Screw, Nut Washer, Pin & Rivate, Press Components, Precision Turn Parts, Special Fastener etc. We also supply as per Customers' Drawing & Sample of Fasteners.

The company is highly committed to continuously improve it’s Quality Management System by designing product as per customer requirements as well as manufacture and supply cost effective and quality products on time. All the product are being manufactured under strict quality control with a team of highly qualified engineers, supported by technically advanced and precision machines and fully equipped R & D Department, Quality control Department and standard Room.

WHAT IS FASTENERS

In mechanics, the need to join pieces like plates, sections, and bars is very common. Any assembly, however simple it may be, requires the union of parts together, but the mechanical parts to be joined require the proper elements of marriage that are named fasteners.

A screw is a piece consisting of a cylindrical body and a screw head, which can take many forms.

The nut is shaped like a prism or cylinder and presents a threaded hole. Through this hole, the nut is screwed to the screw.

The rivet is formed by a cylindrical body and a head. It is manufactured in steel, aluminum, copper or brass. It is used for permanent fixed-tion of two or more pieces.

Pins join articulated parts. In this type of union, one of the pieces can move by rotation.

The peg connect parts that are not interconnected.

The washer is a metal disk with a hole in the center and the body of the screw goes through the hole.

The snap ring is used to prevent displacement of axes. It also serves to position or limit the movement of a piece that slides over a shaft.

QUALITY

Our Manufacturing facility is strategically designed to accomodate various production stages, from raw materail processing to final assembely. It includes dedicated areas for machining, quality control, materail storage and more.

We have wide range of machinery in our works, and about 40,000 kgs. of manufacturing of fasteners.

Quality Policy

“Quality is never an accident; it is always the result of pure intention, sincere effort, intelligent direction and skillful execution”.

Quality Inspection

The test report is recorded and kept for later review. To ensure the excellent quality and reliability of every part and the satisfaction to all customers. "ZERO FAULT" is the goal to our quality assurance system.

Quality Management

Above all, quality means setting the highest standards for ourselves. We are continuously establishing new benchmarks for our products, processes and services. Our quality management system encompasses all current industry standard methods, including machine and process capability analysis, etc. Mayur Industries is committed to customer satisfaction through continuous improvement.

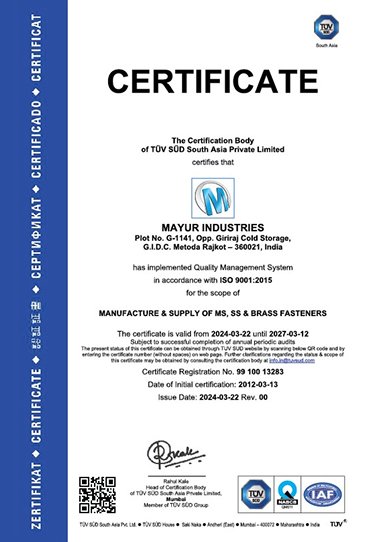

ISO Certificate

Mayur Industries is registered to ISO 9001 :2008, a universally accepted quality assurance designation by TUV SUD South Asia Private Limited.

CERTIFICATION

22/03/2024 - 12/03/2027

ISO 9001 : 2015

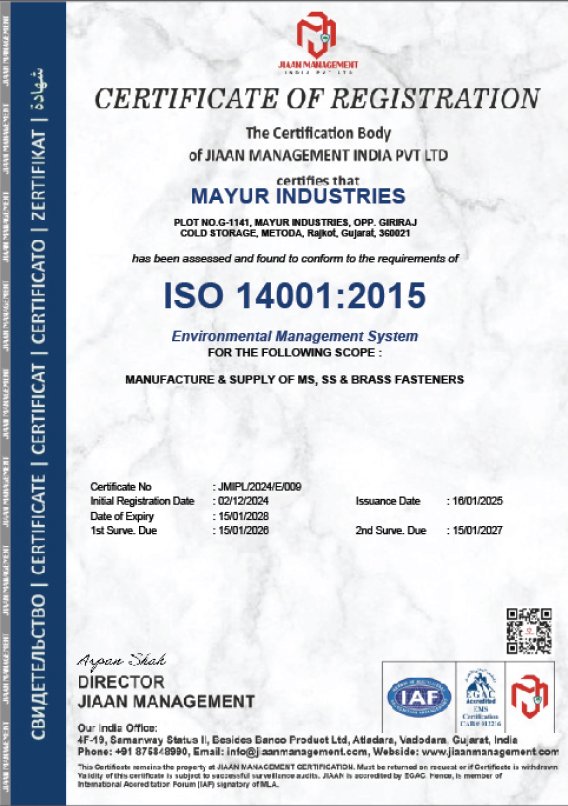

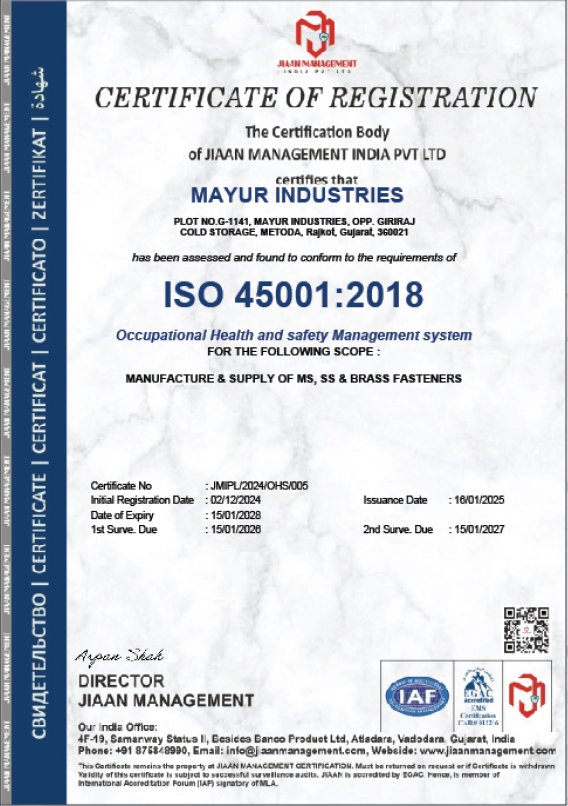

02/12/2024 - 15/01/2028

ISO 14001 : 2015

02/12/2024 - 15/01/2028